Flexible, Secure and Modular System

The Security Printing sector operates in its own production environment, with a particular workflow that differs from the rest of the printing industry. Dedicated to the production of printed documents and products designed to guarantee authenticity, integrity and protection against forgery, this sector plays a crucial role in the security of documents and products in various sectors, including government, finance, commerce and industry.

Aware of the special needs of this sector, SISTRADE has developed a flexible, secure and modular system architecture that supports customization design and quick adaptation for any security requirement. Careful and exhaustive analysis, as well as sustained development to meet requirements, provide a comprehensive response to the special and unique demands of this sector.

Main Features

> Full compliance with security protocols

> "Secure Mobile Warehouse" concept

> Secure data transmission

> Encrypted Users Passwords

> Encrypted data transmission through Wi-Fi connections (HTTPS protocol)

> Pre-assignment access rights per user, module and functionality

> Historical logs per user, device and activity

> Additional Security authentication per User/Device (Security tokens, Biometric, RFID, etc.)

> Full product traceability, from raw materials to dispatched products

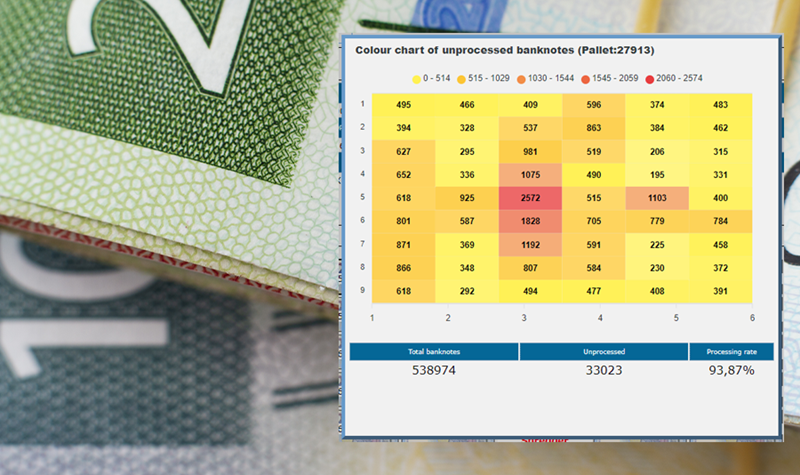

> Connection with BPSs machines to retrieve all information related with the banknotes processing

|

|

|

|

|

|

Identification Documents |

Banknotes |

Labels and Packaging |

Stamps and Tax Documents |

Bank Cards |

Sistrade Software offers a comprehensive suite of features tailored to the unique demands of the security printing & banknotes industry:

This system provides real-time production monitoring to ensure process efficiency and security compliance. It integrates with production machines, seamlessly connecting with printing machines (offset, intaglio, flexo, silkscreen, digital), numbering machines, finishing machines (e.g. hot stamping), quality control machines (e.g. BPS), passport assembly lines and others, facilitating synchronized operations and enabling informed decision-making by gathering data such as machine status (stop/run), speed, and input/output quantities.

Key features include comprehensive ink and printing plate management, tracking their usage, allocation, and lifecycle. It differentiates between setup and production paper, ensuring material consistency. Security labels and serial number tracking enable precise monitoring of raw materials, WIP, and finished products, including banknotes and passports.

Automation extends to packaging registration and WIP identification via barcode/QR codes, enhancing inventory and workflow management. Visual shop floor management tools display performance metrics and machine availability, optimizing resource utilization.

Warehouse Management System (WMS)

Sistrade software ensures secure inventory tracking of high-value materials using barcodes and RFID for efficient stock management. Real-time monitoring provides up-to-date insights on material movement, stock levels, and order status, ensuring tight inventory control.

It guarantees full traceability from receipt to shipment, maintaining detailed logs for audits and compliance. The system optimizes picking, packing, and shipping while integrating seamlessly with other modules for synchronized data flow.

Batch and lot management ensure proper tracking and compliance with security printing industry standards. User authentication and role-based access controls enhance security, while detailed reports provide insights into inventory movements and operational performance.

Secure Mobile Warehouse Management

> It tracks the movement and storage of materials in real time, where each mobile storage unit can be tagged with an RFID tag or barcode, and the system can track its location and contents

> Maintains an audit trail of all transactions (e.g., when a cage was moved, who accessed it, and what items were retrieved or added), ensuring traceability and accountability

> Real-time tracking of mobile units helps prevent loss or misplacement of valuable items by continuously monitoring their movements

Scheduling

Sistrade software optimizes production scheduling using algorithms to minimize setup times and maximize machine utilization while handling complex constraints like resource availability, deadlines, and priorities. It dynamically updates schedules in real time to adapt to shop floor changes, ensuring accuracy.

Visual tools include interactive Gantt charts for identifying bottlenecks and tabular views for detailed task analysis. Resource allocation is optimized to reduce waste, and hierarchical scheduling supports complex production lines.

Features like multiple scenario analysis, job prioritization, automatic alerts, and industry-specific customization enhance decision-making and workflow efficiency. Integration with Sistrade’s Shop Floor Data Collection enables seamless data flow, while the user-friendly interface simplifies scheduling with intuitive navigation and drag-and-drop functionality.

Shop Floor Data Collection

This system enables real-time data collection from shop floor operations, capturing production progress, machine status, and worker activities. It provides immediate feedback to managers for timely decision-making and seamlessly shares data across software modules for enhanced planning and transparency.

By interfacing with machines via IoT devices or APIs, it automates data capture, reducing errors and tracking performance metrics. It monitors raw material usage, manages work orders efficiently, and tracks operator productivity.

Full traceability of production batches ensures compliance, while user-friendly dashboards and detailed reports support analysis and audits. Mobile access enhances flexibility, and role-based access control ensures data security with encryption and authentication mechanisms.

Quality Control

Sistrade software ensures quality control at every stage of production. It starts with incoming material inspections to verify the quality of raw materials, followed by tool inspections before their use. During production, in-process checks detect quality issues early, and final product inspections ensure compliance with quality and security standards.

Detailed records are maintained for each production batch, linking quality data to jobs, machines, and operators for accountability. It supports compliance with industry regulations and custom quality control plans for security products, such as banknotes and passports, and adheres to international quality standards like ISO 9001.

The system generates quality reports, tracks defect rates, and monitors quality KPIs in real time. It also supports historical analysis for continuous improvement and manages non-conformities by logging and triggering workflows for resolution.

Equipment Maintenance

This system features a hierarchical structure of assets, detailing equipment components and parts. It supports preventive maintenance by scheduling routine tasks based on usage or time intervals, and manages corrective maintenance for unexpected equipment issues.

Spare parts and inventory control is included, tracking stock levels, locations, and usage with reorder alerts. Detailed maintenance histories are logged, including task dates and costs, and reports are generated to analyse trends and improve equipment performance.

It integrates with production scheduling to minimize disruptions and offers real-time monitoring of equipment status for proactive maintenance. The system also tracks operator and technician performance by assigning and monitoring tasks.

Continuous Improvement

The Continuous Improvement module is designed to enhance efficiency and maintain high-quality standards in the security printing industry. It identifies inefficiencies or defects by linking issues to specific processes, machines, or materials for targeted action.

It utilizes real-time and historical data to inform process improvements and manages comprehensive OEE (Overall Equipment Effectiveness) metrics: availability, performance, and quality. The system tracks OEE in real time, identifies bottlenecks, and analyzes production waste to reduce inefficiencies.

Benchmarking and goal-setting features enable performance comparisons across different shifts, machines, or production lines. Visual dashboards and detailed reports provide insights into OEE analysis, trends, and comparisons. Real-time alerts notify users of performance drops or prolonged downtimes.

The module also categorizes downtime reasons, offers actionable insights, and promotes a culture of continuous improvement. It aligns with security printing standards and regulatory compliance (e.g., ISO standards) while maintaining traceability for all improvements and changes. Customized reports track the impact of improvement initiatives on efficiency and product quality.

Andon Board

This system displays live data on production performance, machine status, and job progress for operational transparency. It uses color-coded signals to highlight issues like downtime, delays, or quality defects, prompting immediate action.

It seamlessly integrates with other systems for centralized monitoring and synchronized data updates. The information displayed is tailored to security printing needs, including sensitive material usage and quality controls.

It enhances collaboration by prioritizing production tasks and addressing potential disruptions. Alerts and updates are linked to specific jobs or machines, ensuring accountability and compliance with security standards.

Ready to optimise your security printing production?

Contact us for a personalised demonstration of our ERP and discover how our solutions can transform your company.

Sistrade software user testimonials

|

|