PACKAGING PRINTING

Gráfica Ideal is a Portuguese company producing paper carton and corrugated packaging since 1945. In order to adopt the newest technologies to make digital transformation possible and to maintain the highest quality standards, Gráfica Ideal decided to implement - MIS|ERP solution - Sistrade software to manage the company. Sistrade software is a solution able to meet the requirements of the carton and corrugated packaging sector; it is based on the latest information technologies, used to manage all business and production processes.

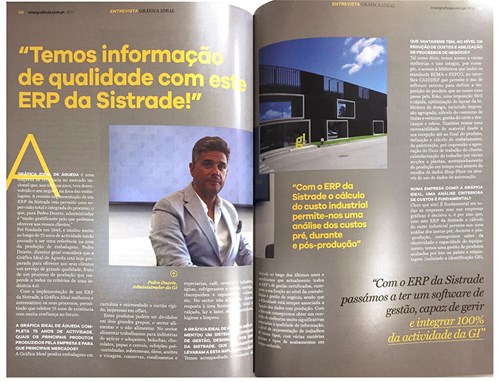

INTERVIEW GRÁFICA IDEAL - Revista IG #213 -VERSÃO PDF

“We have high-quality information with Sistrade ERP!”

GRÁFICA IDEAL DE ÁGUEDA is a reference company on the national market that in recent years has developed its business in the area of packaging. The recent implementation of an ERP from Sistrade has allowed a total and integrated supervision of the process, which for the general manager of the company - Pedro Duarte is “very rewarding given what we can offer to our customers.” The company was founded in 1945 and has changed a lot over 75 years of activity, becoming a reference in packaging production. Pedro Duarte believes that Gráfica Ideal de Águeda is today prepared to offer its customers high-quality service, the result of a production process that meets all the criteria of Industry 4.0. With the implementation of Sistrade ERP, Gráfica Ideal improved and automated its processes, all this allowed celebrating 75 years of existence with great confidence in the future.

IG - GRÁFICA IDEAL DE ÁGUEDA CELEBRATES 75 YEARS OF ACTIVITY. WHAT ARE THE MAIN PRODUCTS PRODUCED BY THE COMPANY AND WHAT ARE THE MAIN MARKETS?

PD - Gráfica Ideal produces carton, micro-corrugated and rigid cardboard packaging printed in offset. These products can be divided into two major groups, food and non-food sectors. In the food sector, we work for the sugar and sweetener industries, cookies, chocolates, porridge and cereals, pre-cooked meals, desserts, oils, olive oils and vinegar, canned food, condiments and spices, coffee, coffee substitute drinks and infusions, water, soft drinks and juices, beer, champagnes and sparkling wines, wines, etc. In the non-food sector, we provide our products to the pharmaceutical, textile and footwear, home and leisure, household appliances, hygiene and cleaning areas.

IG - GRÁFICA IDEAL DE ÁGUEDA IMPLEMENTED SISTRADE ERP INTEGRATED MANAGEMENT SYSTEM. WHAT ARGUMENTS HAVE LED YOU TO THIS IMPLEMENTATION?

PD - We have followed the evolution of Sistrade over the last few years and we believe that currently, all certified ERP solutions fulfil their function in terms of accounting and business management, the difficulty is always associated with the connection of data with production. With Sistrade we have a set of very significant improvements in terms of the quality of information, when it comes to estimating of works of various types, with various raw materials and post-press operation types in a short time.

“With Sistrade ERP, the calculation of industrial cost allows us to analyze costs before, during and after production”

IG - WHAT ADVANTAGES DO YOU HAVE IN TERMS OF COST REDUCTION AND STREAMLINING OF BUSINESS PROCESSES?

PD - As I said, we have access to several improvements and this includes, for example, access to the library with the ECMA and FEFCO standards, access to CAD/DXF interface that allows the use of external software, in our case Esko, for a quick and easy product imposition, optimization of the design library layout, including gang printing, calculation of the consumption of inks and varnishes, management of cutting, stripping, embossing. We also have traceability of the material from its reception to the finished product, definition and calculation of packing, palletizing, pre-press and approval of the client's workflow, work scheduling by various sections and plants, real-time production monitoring through the collection of Shop-Floor data or through the use of automation data.

“With Sistrade ERP, we now have management software, capable of managing and integrating 100% of Internal Management activities”

IG - IS CAREFUL COST ANALYSIS FUNDAMENTAL IN A COMPANY SUCH AS GRÁFICA IDEAL?

PD - It is indeed! It is fundamental in all companies but in printing industry companies it is decisive and, that is why, with this ERP from Sistrade the calculation of industrial cost allows us to analyze the costs before, during and post-production, we get to know the equipment effectiveness and capacity, we have finished products management by lot or pallet and labelling (including GS1 identification, carton label, pallet label...), and we proceed with invoicing and the quick dispatch of finished goods.

“Currently, at Gráfica Ideal, together with Sistrade, we are following the Fourth Industrial Revolution, also known as Industry 4.0”

IG - THE PROCESS OF IMPLEMENTING AN ERP SUCH AS SISTRADE IN A COMPANY WITH THE DIMENSION AND COMPLEXITY OF THE PRODUCTIVE PROCESS AS GRÁFICA IDEAL DE ÁGUEDA IS CERTAINLY A LONG PROCESS. HOW DID THIS PROCESS WORK?

PD - At Gráfica Ideal we had a management software that integrated the accounting and management business operations, but the integration with the areas of technical/production processes and estimating were carried out by “fragile” software that worked in isolation in which the common solution for “integration” was almost always the Excel sheet. With Sistrade ERP, we now have management software, capable of managing and integrating 100% of Internal Management activities, from the financial area, supply chain, operations, HR, production control, planning, technical office, quality control, laboratory and equipment maintenance. The experience in the printing industry shown by Sistrade was critical in our decision. Currently, at Gráfica Ideal, together with Sistrade, we are following the Fourth Industrial Revolution, also known as Industry 4.0, which is characterized by the technological fusion between physical, digital and human systems. With Sistrade, it was possible for Gráfica Ideal to prepare the way for Automation, which consists of creating new business models. On an increasingly demanding market, many companies are already looking to integrate the specific needs and preferences of each customer into the product. The customization of the product by the customers tends to be a variable to add up in the manufacturing process. Only “smart” industries will be ready to ensure the customization for each customer, adapting to their needs.

IG - HOW MUCH TIME HAS PASSED FROM THE DECISION TO THE COMPLETE IMPLEMENTATION OF ERP?

PD - The implementation of a new ERP, transversal to the entire organization is a long process that poses an enormous challenge, generating tension and enormous pressure on the entire organization. In 2018 we decided that the time had come for each of us, individually and collectively, to “reflect” on the quality of our information and its future. This reflection led us to invest in Sistrade as a partner for the implementation of the new ERP. Today, we are able to know a detailed cost of “things”, before, during and after the production process automatically.

IG - WHAT WERE THE MAIN CHALLENGES WHEN MAKING THE DECISION ABOUT ERP?

PD - At the beginning of the project together with Sistrade we identified the 5 main threats of a new ERP implementation that ended up not requiring effort, dedication or requiring resources. Then the act of devaluing that is the natural tendency in order to resist change on the part of our employees and the difficulties that can happen due to the keeping old habits. There is always a reluctance to abandon spreadsheets, which is a paradigmatic example of this problem. Another important challenge was the old system and the right and planned time for it to be cut off. All of this is a way to move the employees out of their comfort zone and learn something new.

“All departments must be aware of the importance of passing only the correct information”

IG - WHAT ARE THE MAIN ASPECTS OF THE RESISTANCE TO CHANGE?

PD - Employees may not be interested in learning the software in-depth or mastering it perfectly, nor wanting to understand the importance of the correct data, especially when migrating to a new ERP. All departments must be aware of the importance of passing only correct information and taking the opportunity to clean up past mistakes; a relevant aspect is that in certain situations, customers are expected to understand the problems that may arise after the implementation. However, hardly any company can afford this luxury. With this in mind, everyone at Gráfica Ideal got to know the difficulties that we would encounter and that was crucial. This process was long and hard, but the management was always present, participating and interacting, side by side, with all departments, making joint decisions individually and collectively. Today it is very gratifying to be able to look at the quality of the information we have to offer our customers.

Website: www.graficaideal.pt