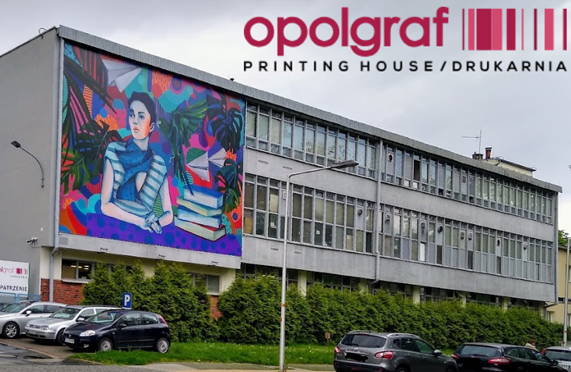

BOOK PRINTING

Opolgraf is acknowledged as one of the best companies of like capabilities in the country, with approximately 8 million books under 1.700 titles produced annually. The co-operation with the major publishers in Poland and many foreign publishers proves that Opolgraf is ready to fulfill the most stringent criteria. Flexibility, openness, reliability, delivery-on-time and immediate communication with the clients are Opolgraf's strengths and targets of continuous improvement policy.

Offering printing services at the best combination of price and quality has led Opolgraf to take a decision to implement MIS|ERP system. Opolgraf has chosen Sistrade® solution for many reasons, one of them is the ease of access to all the features of MIS|ERP using a laptop, tablet or smartphone, regardless of operating system or browser.

Interview with Bartosz Mazurkiewicz – Vice-president of Opolgraf printing house about the details of Sistrade MIS|ERP system implementation and the benefits it brought.

Sistrade MIS|ERP in Opolgraf printing house

“Here and now” thanks to Sistrade - PDF Version

I think Opolgraf needs no introduction, however, could you present the company in a few words?

Opolgraf is one of the leading book printing houses in Poland. Its innovation and quality of services are confirmed by numerous awards and certifications, such as Diamond Forbes Award, Gazele Biznesu or ISO quality certificate. The company is repeatedly distinguished and appreciated by publishers for communication, quality and timeliness. Every year, we are among the best in the most important industry rankings organized by Wydawca or Magazyn Literacki Książki magazines. Opolgraf is proud of over 70 years of experience, which translates into striving for the highest level of professionalism.

What is a typical finished product of Opolgraf?

It is, no doubt, a book. Paperback and hardcover books. Presently, the production of books takes place in over 6,000 sq meters production hall located in Opole. Our production hall is equipped with Heidelberg sheetfed offset machines, the last one installed in 2016. We also have rotary coldset machines, they significantly increase our production capacity. In post-press, we have two Müller Martini lines for the binding and the recent investments in the new hardcover binding line directly affected the level of domestic and export sales.

How big is the share of export?

Poland still remains our main market, although we currently export over 35% of finished products. We are present at the fairs in London, Paris, Gothenburg, Frankfurt, Bologna and of course at all book fairs in Poland. The main export destinations are the Scandinavian countries and the United Kingdom.

Nearly three years ago, you have decided to purchase an integrated MIS|ERP system from SISTRADE. Have you already obtained the return on investment?

Yes, absolutely. The return on investment took place in a very short time, already at the stage of system implementation. The first step during the implementation is the parameterization of the estimating module, which consists of defining all operations, raw materials, processes in our printing house. We simply transfer the realities of the printing house into the IT dimension. In my opinion, the most important feature of the software is the ability to make online estimates. Nothing makes such an impression on our clients as the possibility of making the initial estimate at the stand during the book fair.

I shall guess that the most difficult stage was the implementation of the system, during which the cooperation of both implementation teams (SISTRADE and OPOLGRAF) was crucial.

Definitely, to effectively complete the implementation process, the human factor and cooperation of the two parties is the most important. I admit that the implementation process is time and energy-consuming. This is the time when the company begins to make a kind of examination of conscience. We reconsider the production costs of finished products. We look closely at the processes. Every element of the company's life is carefully taken under the microscope. Already at this stage, we realized that the range of products that seemed to be profitable, in reality was not. Products that began to record sales growth were less profitable in production than others. Apparently a simple observation, however, if it were not for the implementation of the system, this information would most likely go unnoticed.

I understand that after it was easier

It is never easy and never has been. Opolgraf never goes for the easy; we have set Sistrade very high demands.

Did you set goals during implementation? What did you want to achieve after implementing the MIS|ERP system?

Our first goal was to create an accurate tool for estimating of the finished product. In this estimate, we wanted to include everything. Starting from the basis - a type of substrate, printing process, levels of difficulty at all stages of production, from imposition to post-press. This is the basis.

The estimation module is the basic feature of any MIS|ERP system, so why SISTRADE?

For us, the precision of estimates was important, and not every supplier was able to provide it. For example, the calculation of packing of books, stacking into pallets, placing into delivery trucks was also important. As I mentioned, a very large percentage of production is exported. Each additional cubic centimeter of the shipment is an additional cost to us. Currently, the system automatically calculates the most advantageous packing method. Imagine that although we have to define over 100 operations, and the product is a book, i.e. a product made up of many elements, the time to complete one estimate is around 3 minutes.

Was production scheduling and management also an important issue for implementation? I know that you have replaced one of the leading scheduling systems by Sistrade solution.

Yes, it is true. A few years ago, we made large investments in a production scheduling system. It was software that, incidentally, operates the airport in Vienna. The enormous possibilities offered by the system are too complicated and have remained largely unused in our printing realities. After configuring Sistrade estimates and production management modules (mainly for data acquisition from the binding machine), we implemented a production scheduling module from Sistrade.

Was the configuration of Sistrade scheduling module time-consuming?

On the contrary, the implementation time of the scheduling module lasted practically a week. Scheduling really begins at the stage of estimation. A well-configured estimates module, where the time of operation is properly defined, is the foundation for good scheduling. Simultaneously, the scheduling is connected to the production module, i.e. production machines. Scheduling “sees” what is currently happening in production. Dedicating more time and energy to accurately configured estimation module brings us benefits in the form of fast production of job orders and accurate data during scheduling.

How many users currently use Sistrade system?

Nearly every employee of the printing house in one way or another has contact with the system, from the operators in production, technology department, to the management of the company. I would like to add that Opolgraf employs over 140 people.

What was your first contact with SISTRADE company?

It was a conference organized in Porto together with Grafikus, SISTRADE business partner in Poland. It was there, that I had the opportunity to learn about the company structure and to see the case of implementation. It was then, that the first spark of interest appeared. Next, the presentation of the system to the entire Opolgraf team was completed with a positive decision. The fact of the existence of a Polish partner, namely Grafikus company, significantly influenced our decision.

Weren’t you uncertain about a supplier from Portugal? Wouldn’t it be better to bet on a global player solution in the field of printing software?

In the times of globalization and the internet of things, the origin of the supplier is of no importance. For me as the decision-maker and manager, the most important was the experience of the system’s supplier. SISTRADE has implementations in 25 countries in many printing houses in various parts of the world and therefore, has developed know-how. So why not use the experience of SISTRADE and not only for process automation, but also to reach a higher level.

Was this the most important argument when choosing a system?

Yes, that was the most important argument. The second advantage of Sistrade system was its architecture. It is a web-based system, thus, it gives enormous mobility. Our salespeople, at the customer’s premises, can make a quick estimate on the tablet. The production manager on the smartphone has a preview of the production plan. We live in the mobile era and we will not reverse this trend. The customers require everything for “here and now” from our printing house, I require all the data “here and now” from my organization.

Can you recommend SISTRADE to other printing houses?

I think that from what I have said it is not difficult to read that I consider the decision to implement Sistrade software a satisfying decision. With a clear conscience, I can recommend the system and SISTRADE implementation team to everyone.

Website: https://opolgraf.com.pl